The Impact Of Laser Cutting On Design Flexibility

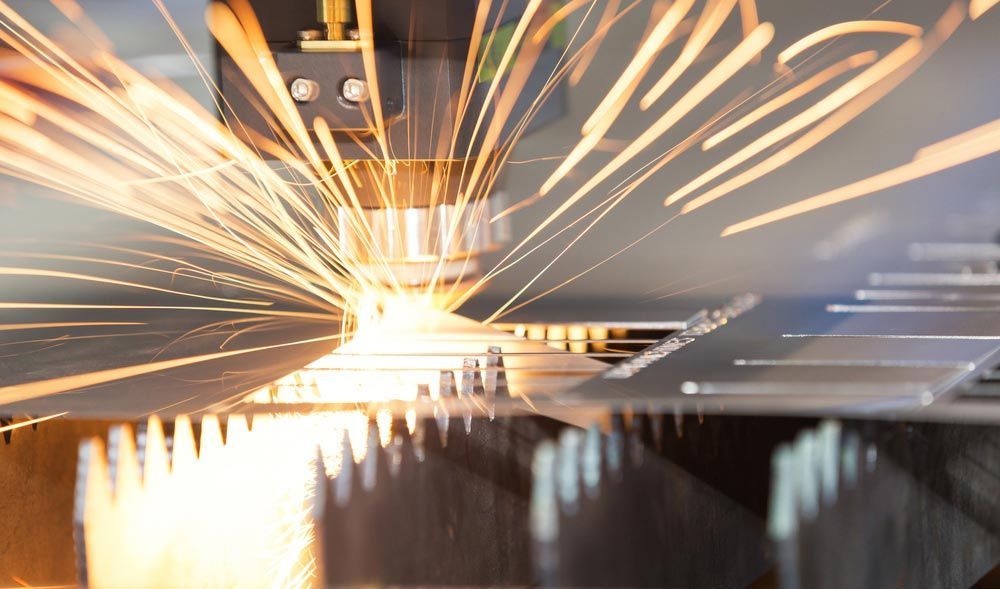

Design innovation thrives on the freedom to shape, refine, and bring ideas once limited by tooling or tolerance to life. In modern manufacturing, laser cutting has emerged as a transformative solution, enabling precision, versatility, and speed in design execution. Whether it’s creating bespoke architectural details or functional engineering components,

laser cutting empowers creators to test boundaries without compromising on quality or turnaround. This blog explores how this technology enhances design flexibility across industries, helping you bring your most ambitious ideas to life.

Precision Cutting Enables Complex Architectural Detailing

Architectural design often calls for high levels of intricacy and repetition—attributes that laser cutting handles with ease. From feature screens and decorative facades to customised signage, the precision of laser cutting enables consistently sharp edges and intricate geometries that are near impossible with traditional methods.

- Delivers exact repeatability, ideal for large-format facade panels or screens

- Maintains tight tolerances even in detailed cut-outs and curves

- Ideal for metal feature pieces such as balustrades, wall art or light diffusers

- Supports aesthetic innovation without compromising on structural integrity

For architects, this means fewer limitations and more creative options when visualising bespoke design elements.

Streamlining Product Prototyping with Laser Efficiency

Rapid prototyping is essential in modern product design, and laser cutting offers an unmatched combination of speed and precision. Traditional prototyping methods often involve costly tooling and manual processing, but laser cutting streamlines this workflow, allowing designers to test and iterate designs in a fraction of the time.

- Produces accurate one-off pieces for functional or aesthetic testing

- Allows fast turnaround, reducing the product development cycle

- Simplifies adjustments with minimal disruption between design iterations

- Supports a wide range of materials, including mild steel, stainless steel and aluminium

With reduced lead times and fewer production constraints, product designers can accelerate time-to-market without sacrificing innovation.

Design Iteration Made Easier with Digital Cutting Files

Laser cutting relies on digital design files, significantly simplifying versioning, replication and alteration of design elements. Whether adjusting a few millimetres in a mechanical part or re-scaling an entire panel layout, designers can implement changes quickly and confidently.

- No physical tooling is required, enabling instant file-to-part manufacturing.

- Simple digital file updates streamline design modifications

- Ensures dimensional accuracy across iterations

- Ideal for mass-customised products or limited-run design variations

This digital-to-physical flexibility is especially valuable in fields requiring frequent product revisions or tailored outcomes.

Achieving Seamless Material Integration Across Designs

Blending multiple materials in a single product or installation is a staple of contemporary design, particularly in architectural and industrial contexts. Whether it's combining steel with timber for a rustic-modern facade or integrating metal and acrylic in lighting features, these hybrid applications demand precision to achieve clean transitions and structural integrity. Laser cutting makes this process more controlled and predictable by delivering consistent, high-accuracy cuts across diverse materials.

- Enables integration of materials like metal, acrylic, timber, and composite panels into a unified layout

- Supports precision alignment of components for accurate, flush fitting during multi-material assembly

- Facilitates complex jigsaw-style fittings, overlays and mechanical joins without the need for secondary tooling

- Reduces dimensional errors in hybrid designs involving both structural and decorative elements

- Accommodates a wide variety of thicknesses and surface treatments while maintaining edge quality

For designers, fabricators and engineers who frequently work across materials, laser cutting unlocks the potential for more ambitious and cohesive designs, improving build quality while streamlining fabrication workflows.

Pushing Creative Boundaries in Facade & Surface Design

Creative expression is vital in architecture and industrial design. Laser cutting removes barriers that once restricted form and pattern, allowing designers to explore bold ideas in surface treatment and architectural ornamentation.

- Creates customised facade cladding with repeating or organic patterns

- Supports layered and multi-dimensional detailing in building elements

- Enables perforation designs for solar shading, airflow or acoustic purposes

- Enhances surface textures through patterning without requiring secondary processes

From expressive perforations to light-manipulating layers, laser cutting transforms plain metal sheets into captivating architectural surfaces.

Reducing Waste Through High-Precision Cuts

Sustainability is no longer optional—it’s a core requirement in design and production. Laser cutting reduces material waste by maximising material utilisation through nesting software and fine kerf width cuts.

- Minimises off-cuts thanks to precise nesting capabilities

- Produces cleaner cuts, reducing rework and scrap

- Suitable for recycled or repurposed materials with minimal degradation

- Contributes to environmentally responsible manufacturing practices

Laser cutting is a sustainable production choice for projects with green building targets or LEED considerations.

Customisation at Scale for Engineering Components

Engineering often demands precision and consistency, especially when components must be tailored in small batches or scaled efficiently. Laser cutting excels at this balance, enabling cost-effective customisation without compromising accuracy.

- Allows quick production of low-to-medium volume part runs

- Ensures high repeatability across complex or uniquely shaped parts

- Eliminates the need for hard tooling, reducing costs in custom fabrication

- Supports modifications based on specific project needs or constraints

Engineers gain the freedom to adapt, iterate or localise design elements without resetting entire manufacturing workflows.

From Sketch to Steel: Bringing Vision to Life

Design flexibility is about turning ideas into tangible results. Laser cutting bridges the gap between digital creativity and physical execution, translating even the most intricate sketches into precise metal components.

- Accepts digital file formats directly from design software (e.g. DXF, DWG)

- Cuts complex designs in a single operation, ensuring design integrity

- Ideal for turning concept mockups into full-scale displays or structural parts

- Delivers clean, burr-free edges suitable for final use or assembly

Whether you’re building a statement piece or a structural system, laser cutting allows you to realise your design without compromise.

Ready to Transform Your Designs?

At Agriweld Engineering, we offer advanced laser-cutting services that empower designers, engineers and architects to create without constraint. Our state-of-the-art laser cutter in Dubbo delivers the precision, flexibility and speed you need to bring your vision to life. From one-off prototypes to production-scale cutting, we help streamline your workflow and expand your creative possibilities.

Get in touch via our contact page or give us a call for more information or to book a consultation.