Laser Cutting Dubbo

High-Precision Laser Cutting Services Dubbo Depends On

Welcome to Agriweld Engineering, your trusted partner for high-precision laser cutting services in Dubbo. We specialize in providing expert solutions for all your cutting needs, offering custom services that cater to a wide range of industries. With years of experience and a team of dedicated professionals, we are committed to delivering outstanding results using state-of-the-art technology. Whether you're working on a small project or a large-scale production, we ensure every cut is accurate, efficient and tailored to your specifications.

At Agriweld Engineering, we deliver accurate and reliable laser cutting tailored to your needs. Our advanced process ensures clean cuts and exceptional results for a wide range of applications.

Laser-Focused on Quality

Your Laser Cutting Specialists

- HSG 2.5kw Fibre optic laser

- 3mx1.5m duel bed

- Mild steel Max thickness 16mm

- Alloy max thickness 10mm

- Stainless max thickness 10mm

What is Laser Cutting?

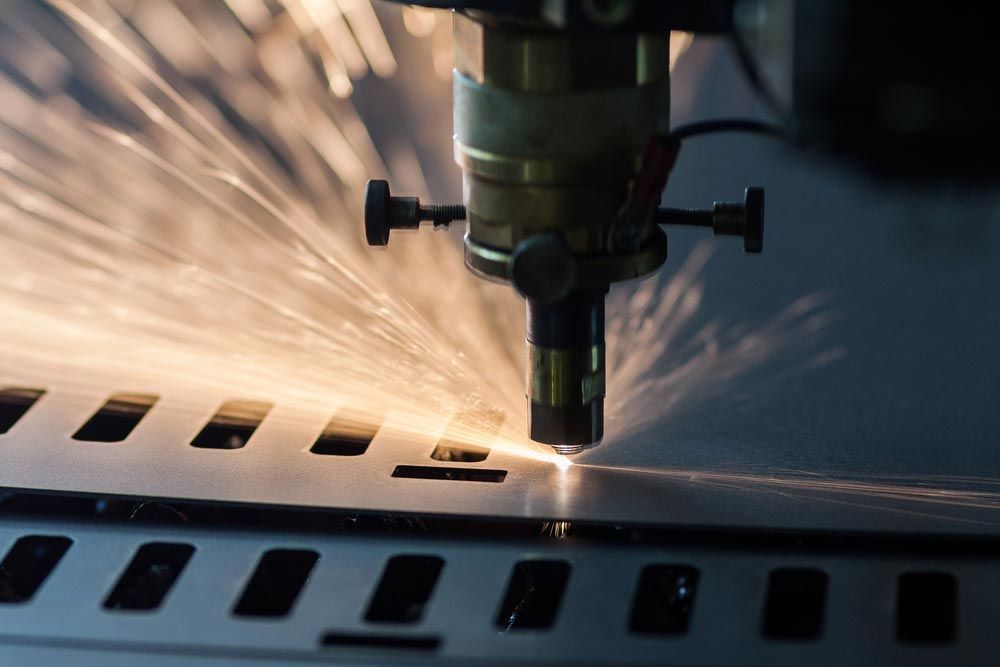

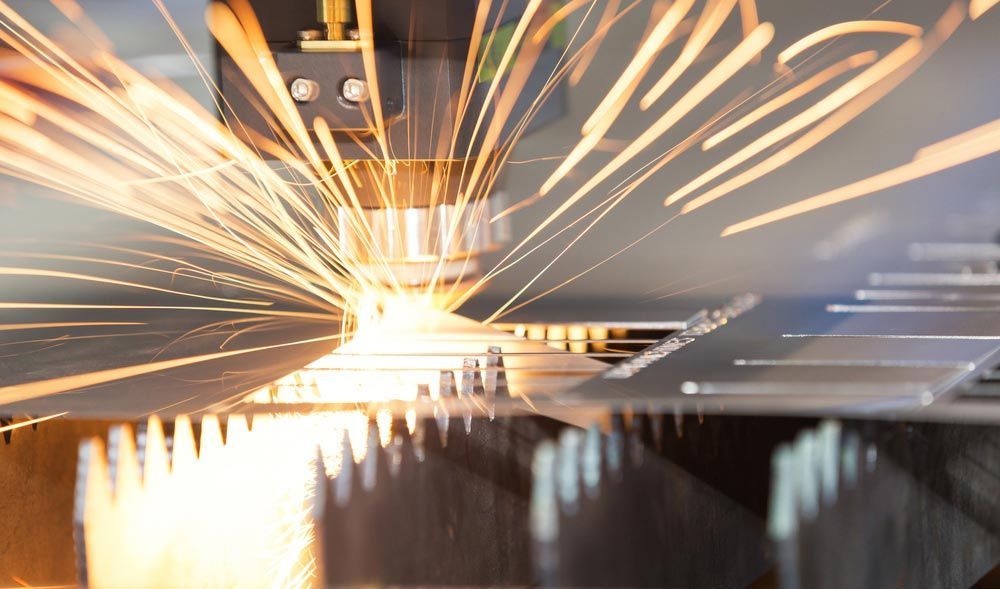

Laser cutting technology uses a focused laser beam to cut highly precise and accurate materials. The process involves directing the laser beam onto the material, which absorbs the light energy, causing it to melt, burn, or vaporise, resulting in a clean cut. This method is widely used across various industries, including manufacturing, construction, and custom metal fabrication, due to its ability to produce intricate designs and complex shapes that are difficult to achieve with traditional cutting methods.

One of the key advantages of laser cutting is its versatility in handling a wide range of materials, such as metals, wood, plastics, and fabrics. The non-contact nature of the process minimises material distortion and reduces contamination, ensuring high-quality results. Additionally, laser cutting offers rapid processing speeds and automation capabilities, which enhance production efficiency and reduce labour costs.

Safety Considerations in Laser Cutting

While laser cutting offers numerous advantages, safety considerations must be addressed to protect operators and maintain a safe working environment.

Exposure to laser beams, particularly those from Class 3B and 4 lasers, can cause severe eye injuries, including blindness and serious skin burns. Even brief exposure to the often-invisible laser beam can result in injury. To mitigate these risks, operators should wear appropriate laser safety glasses and adhere to strict safety protocols.

Additionally, the laser-cutting process can generate fumes and gases that may be hazardous if inhaled. Proper ventilation systems should be installed to remove these emissions from the work area. Regular equipment maintenance and adherence to safety guidelines are crucial to prevent accidents and ensure the well-being of personnel involved in laser cutting operations.

By understanding the laser cutting process, its advantages, and safety measures, industries can efficiently use this technology for precise cutting solutions..

Applications of Laser Cutting

At Agriweld Engineering, we offer professional laser cutting services in Dubbo, working with a wide range of industries including construction, manufacturing, and custom metal fabrication.

With years of experience, we have built a reputation for providing high-quality laser cutting services to businesses across Dubbo and beyond. We work with a diverse range of industries, including automotive, aerospace, agriculture and more, offering tailored solutions for each sector's specific needs. Our team’s expertise ensures that your project is executed with the utmost precision, regardless of the industry or material requirements.

Our advanced laser cutting equipment delivers precise, clean cuts—ideal for projects that require detailed work and high accuracy. Utilising state-of-the-art fibre optic laser technology, we guarantee exceptional precision in every cut, which is perfect for projects that demand high detail. From small components to complex designs, our equipment ensures clean, smooth edges, reducing the need for additional finishing work and enhancing the overall quality of your project. With the ability to handle various materials like mild steel, stainless steel and alloys, we are well-equipped to bring your design ideas to life with remarkable accuracy and speed.

We cut everything from machine parts and structural components to signage and decorative metalwork, tailoring each job to your specifications. Whether you're looking for functional machine parts or intricate decorative metalwork, our laser cutting services cater to a wide variety of needs. We specialise in creating components for industrial machinery, custom signage and architectural features, delivering high-quality, bespoke solutions that align with your vision. Each project is treated with the utmost care and attention to detail, ensuring that your specifications are met perfectly.

This service is perfect for applications needing consistent results and smooth edges. Our laser cutting service is designed to deliver consistent, high-quality results every time, making it the ideal solution for industries that require repeatable accuracy. The precision of laser cutting makes it the go-to method for cutting intricate shapes, designs and parts that need to fit together perfectly without the need for further finishing. Whether you need hundreds of identical parts or a one-off custom design, our service ensures that every piece meets your expectations.

Whether your project is large or small, we ensure reliable turnaround and attention to detail. In addition to laser cutting, we also provide plasma cutting, oxy cutting, and pipe cutting. No matter the size of your project, we guarantee quick and reliable turnaround times without compromising on quality. Our efficient laser cutting processes and skilled team ensure that your project is completed on schedule, helping you meet tight deadlines. We understand the importance of timely delivery, which is why we prioritise effective communication and transparent processes to keep you informed throughout every stage of production.

Contact Agriweld Engineering on

02 6882 2934 to find out how we can help.

Advantages of Fibre Optic Laser Cutting

Agriweld Engineering uses state-of-the-art HSG 2.5kw fibre optic laser technology to deliver unmatched precision and speed. This cutting-edge system allows us to handle a variety of materials, including mild steel up to 16mm thick, as well as alloy and stainless steel up to 10mm thick.

Our advanced fibre optic laser cutting system is designed to handle a wide range of materials with exceptional accuracy. This technology ensures that every cut is precise, clean and consistent, making it ideal for everything from delicate, small components to larger, more intricate designs. The fibre optic system allows for faster cutting speeds compared to traditional laser systems, reducing turnaround time and increasing overall efficiency.

Fibre optic laser cutting delivers clean, precise edges with minimal finishing. It’s fast, efficient, and works well on different metals and complex designs. The high-powered fibre optic laser ensures that the edges of your cuts are smooth and free from burrs, reducing the need for additional post-processing and helping to cut down on both time and costs. Whether you need to create detailed patterns, intricate shapes or simple straight cuts, our fibre optic laser can achieve a level of precision that other cutting methods simply can’t match. This precision makes it the ideal solution for industries that demand the highest levels of accuracy, such as automotive, aerospace and manufacturing.

With our advanced equipment and skilled team, we provide reliable, high-quality laser cutting solutions tailored to your needs. Our team of skilled technicians ensures that every project meets your exact specifications, and we work closely with you to understand the unique requirements of your project. We use advanced CAD software to prepare detailed, custom designs that are fed directly into our laser cutting system, ensuring that the final product is of the highest quality. Whether you need a small batch of precision parts or large-scale production runs, our fibre optic laser technology provides consistent results across all orders. We are committed to delivering fast, reliable service that exceeds your expectations, while maintaining competitive pricing.

Why Choose Our Services for Laser Cutting in Dubbo?

At Agriweld Engineering, we are committed to delivering not only high-quality cuts but also exceptional customer service. When you choose us for your laser cutting needs in Dubbo, you’re choosing a company with the expertise, technology and reliability that ensures your project is in safe hands.

Fast, Accurate and Cost-Effective Laser Cutting

We pride ourselves on providing fast and accurate laser cutting services in Dubbo that don’t break the bank. Our advanced equipment and efficient workflow allow us to complete projects quickly, reducing downtime and ensuring your project moves forward without delays. Thanks to the precision of laser cutting, we also minimise waste, providing a cost-effective solution that helps you save on materials and time. Our commitment to accuracy ensures that each cut meets your design requirements, giving you high-quality results without the premium price tag.

Industries We Serve With Laser Cutting in Dubbo

Our laser cutting Dubbo services are used across various industries that require high precision and quality. Whether you're in construction, automotive, manufacturing or architecture, we have the tools and expertise to support your project needs.

Custom Solutions for Multiple Industries

We offer custom laser cutting solutions for businesses in industries such as automotive, aerospace, construction and more. Our laser cutting services are ideal for producing everything from structural components to small, intricate parts. With our flexible approach, we can accommodate the unique demands of any project, regardless of scale or complexity.

Advantages of Choosing the Laser Cutting Method

Opting for laser cutting provides several benefits:

- High Precision & Accuracy: Laser cutting achieves exceptional precision, allowing for intricate designs and complex shapes that are challenging with traditional methods.

- Versatility: It can process various materials, including metals, wood, plastics, and fabrics, making it suitable for diverse applications.

- Non-Contact Process: The laser beam does not physically touch the material, reducing the risk of contamination and minimising material distortion.

- Efficiency: Laser cutting offers rapid processing speeds and can be easily automated, increasing productivity and reducing labour costs.

- Minimal Waste: The precision of laser cutting results in less material waste, contributing to cost savings and environmental sustainability.

Types of Laser Cutting

There are several types of laser cutting technologies, each suited for different materials and applications:

- CO₂ Lasers: A gas mixture produces the laser beam, which is ideal for cutting non-metal materials like wood, plastic, and fabrics.

- Fiber Lasers: Use optical fibres doped with rare-earth elements to generate the laser beam, making them suitable for cutting metals such as stainless steel and aluminium.

- Nd:YAG & Nd:YVO (neodymium-doped) Lasers: Used for both high-powered and low-powered operations. Each type offers different benefits and is chosen based on material type and thickness.

The Laser Cutting Process: Fast, Efficient and Precise

The laser cutting process is designed for efficiency and precision, ensuring that every project is completed with the highest level of accuracy. Our team uses advanced software to create digital designs, which are then translated into precise cuts by our

laser cutting machines. This process ensures that the end product meets your exact specifications.

How Our Laser Cutting Service Works for You

When you work with us, you can expect a streamlined process from start to finish. First, you provide your design, and we use our laser cutting software to generate the cut paths. Next, our state-of-the-art laser machines perform the cutting process, ensuring precision and efficiency. The final product is carefully inspected to ensure it meets your expectations before delivery. Whether you need a single prototype or a large production run, we handle every step of the process with care and precision.

Get in Touch with the Best Laser Cutting Services in Dubbo

Ready to bring your project to life with the best laser cutting Dubbo has to offer? Our team at Agriweld Engineering is here to provide you with high-quality, precision cuts that meet your exact specifications. We pride ourselves on offering fast, reliable and cost-effective solutions for all your laser cutting needs.

Contact Us Today for Your Laser Cutting Needs

If you have any questions or would like to discuss your project, don’t hesitate to reach out to us. Our team is ready to assist you and provide a tailored solution to meet your needs. Contact us today for a consultation or a quote, and let us show you how our laser cutting services can help you achieve your project goals with precision and ease.