Uses Of Sheet Metal Fabrication

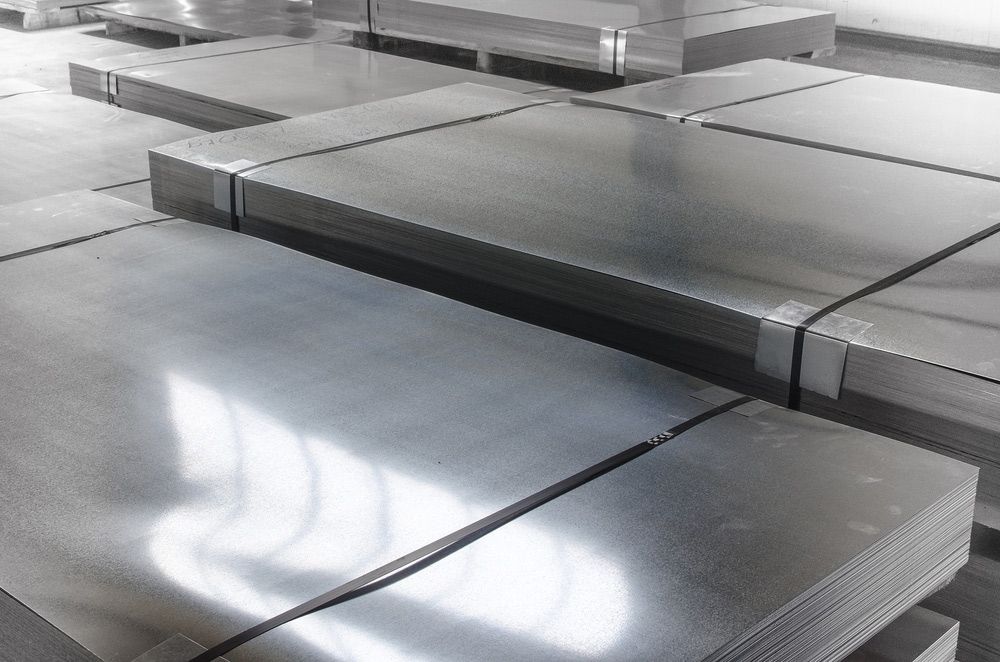

Sheet metal fabrication is a complex and versatile process that has become a cornerstone of the manufacturing industry. It involves shaping and manipulating thin sheets of metal into various forms and products using specialised equipment and techniques. From automobile parts to household appliances, sheet metal fabrication is used in numerous applications across a wide range of industries. In this blog post, we'll explore the many uses of sheet metal fabrication and the benefits it offers to businesses and consumers alike.

Exploring The Versatility Of Sheet Metal Fabrication

Sheet metal fabrication is a cornerstone in manufacturing, offering unparalleled flexibility and innovation. This process transforms flat sheets of metal into various shapes and sizes tailored to specific industry needs.

Building and Construction

Sheet metal fabrication can be used to create roofing, cladding, ductwork, gutters and other structural elements for buildings and infrastructure. Sheet metal fabrication can also produce decorative features such as railings, balustrades and sculptures.

Aerospace and Aviation

Sheet metal fabrication can be used to create parts and components for aircraft, rockets, satellites and space vehicles. Sheet metal fabrication can also produce tools and equipment for the maintenance and repair of aerospace vehicles.

Medical and Healthcare

Sheet metal fabrication can be used to create medical devices such as implants, surgical instruments, prosthetics and orthotics. Sheet metal fabrication can also produce equipment and furniture for hospitals, clinics and laboratories.

Food and Beverage

Sheet metal fabrication can be used to create food processing and packaging equipment, such as conveyors, mixers, slicers and sealers. Sheet metal fabrication can also produce storage and dispensing systems, such as tanks, silos and vending machines.

Automotive and Marine

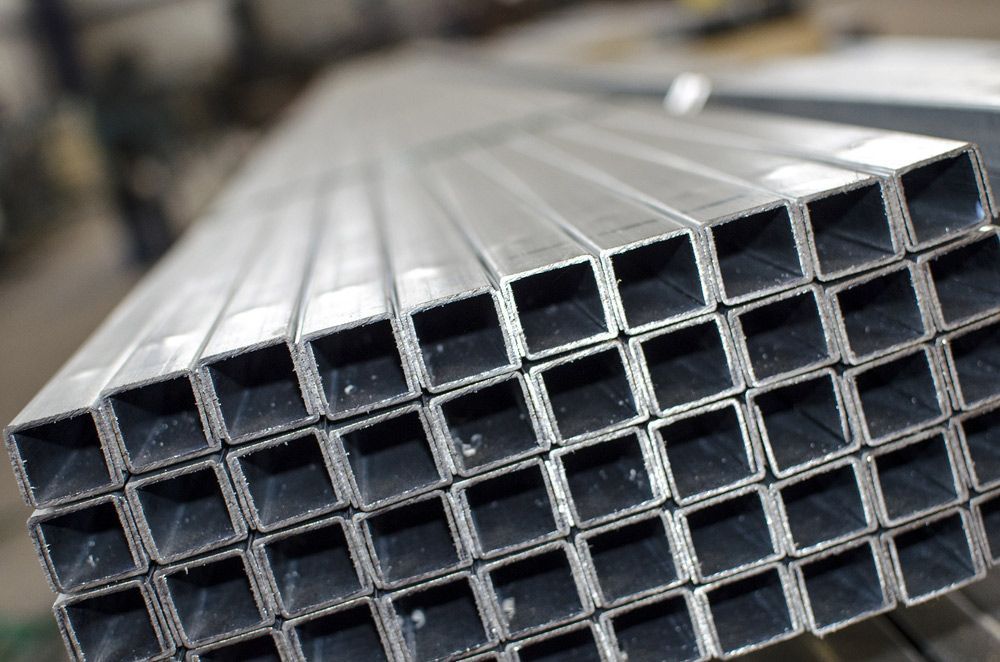

Sheet metal fabrication enables the production of durable, lightweight components for modern vehicle and watercraft designs. This process supports the creation of everything from chassis parts to intricate engine components, enhancing performance and fuel efficiency.

From Concept To Creation: The Process Of Sheet Metal Fabrication

Understanding the journey from raw material to finished product reveals the meticulous craftsmanship involved in sheet metal fabrication.

- Design and Prototyping: The process begins with a detailed design phase, where ideas are transformed into tangible prototypes. This stage is crucial for identifying potential issues and ensuring the final product meets all specifications.

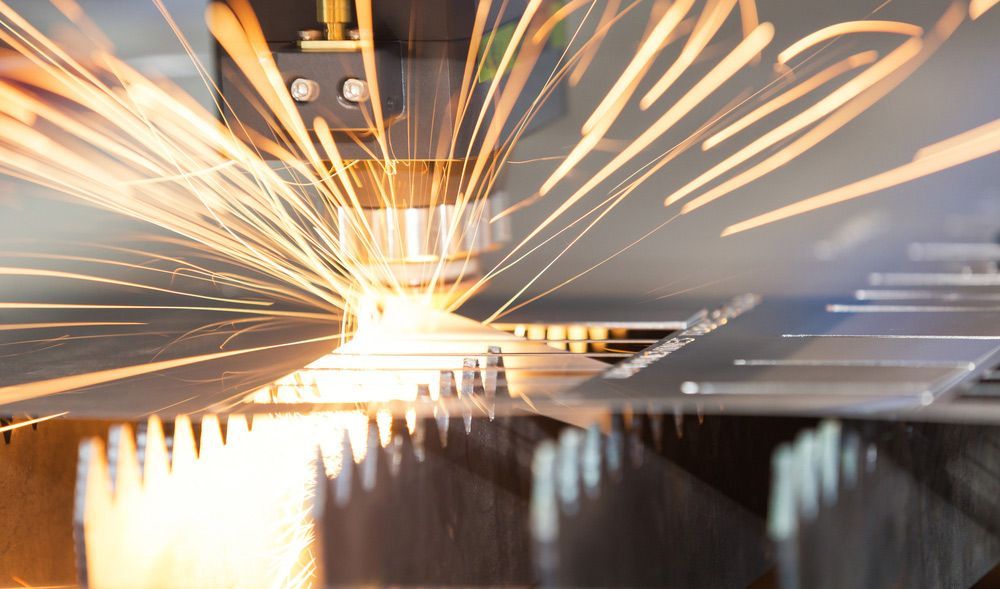

- Cutting and Forming: Utilising advanced machinery, the metal is then cut and formed into the desired shape. This can involve various techniques such as laser cutting, punching and bending.

- Assembly and Finishing: The components are assembled, often involving welding or other joining methods. The final step includes finishing touches like painting or coating, which protect the metal and enhance its appearance.

Elevate Your Projects with Expert Fabrication

Sheet metal fabrication is a highly versatile and valuable technique that can create a wide range of products and components for various industries. At Agriweld Engineering, we take pride in our expertise and commitment to quality in every project we undertake. We offer a comprehensive range of fabrication services, including welding, laser cutting, plasma cutting and oxy cutting, all tailored to meet your needs. So, whether you're looking for sheet metal fabrication services for the automotive sector, construction or any other industry, don't hesitate to contact us today!

Agriweld Engineering is a local family owned company that has being servicing the central west for over 35 years

QUICK LINKS

BUSINESS HOURS

Mon - Thurs: 7am-4pm

Friday: 7am -1pm

Sat - Sun: Closed

© Copyright 2021 | All Rights Reserved | Agriweld Engineering